Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

Sheet Metal Forming Equipment

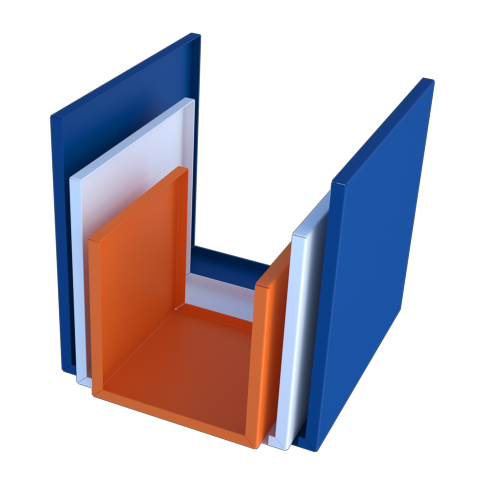

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

Metal Forming Machines in Rockford: Advantages and Disadvantages

A metal forming machine in Rockford is a metalworking machine that shapes metal (usual steel) by deforming it. Metal forming machines are used for many different purposes, such as creating complex metal parts and pieces or shaping metal into sheets of various sizes.

The metal forming machines used in manufacturing today are an important part of the production because they allow for metal parts and components to be created quickly, cheaply, and accurately.

Advantages

One of the most important features of metal forming machines is that they can form metal in ways other methods cannot, like turning a straight piece of sheet metal into an L-shaped part or bending it without causing kinks. This increases production and makes manufacturing better quality products more affordable for companies by allowing them to do their own work rather than outsourcing to another company with expensive machine tools.

Some advantages of using metal forming machines include the ability to create more complex pieces without needing to use expensive tools and wire cutting quality, but there are also disadvantages like high costs and limited capabilities in comparison with other types of machinery.

Disadvantages

Metal forming machines come with their downsides as well; they are very costly upfront and require extensive knowledge about how each one operates before you can use it effectively – not something all businesses have on hand right away when investing in machinery like these types. Another disadvantage is that metal forming machines can be dangerous to operate.

A metal forming machine in Rockford can break easily, metal shavings jam up the machine and they are expensive to purchase. In addition, metal forming machines cannot do as precise of work as other metalworking equipment such as sheet metal brakes or presses.

Furthermore, metal formers require regular maintenance from experienced personnel in order to function properly which adds another expense for companies that use them regularly. Because metal formers need a much larger footprint than some other machinery it is not easy to find places where they will fit into a factory floor efficiently.

Finally, despite their high price tag an operator training program has to be implemented if employees who handle metal former must learn correct procedures well enough so accidents won’t happen during usage of this type.

Our metal forming machine experts have answered some of the most common questions about metal forming machines and discussed what you can expect from a BrakeMate service. These are just a few of the many reasons why we’re your best choice for all things related to metal forming machines. Let us help you find out how much time or money you could save by investing in our services today! Contact one of our representatives at (815) 315-7906.