Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

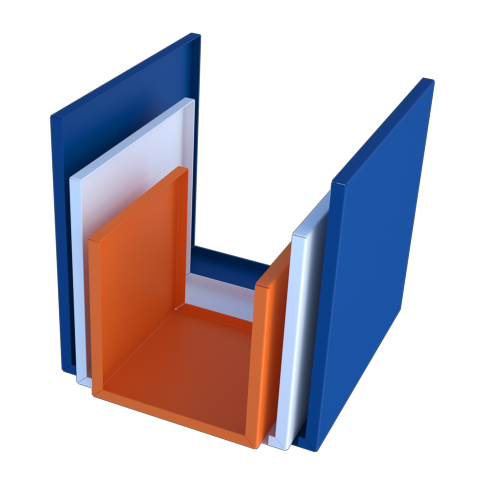

Sheet Metal Forming Equipment

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

Producing Sheet Metal Forming Equipment in Rockford

Sheet metal forming equipment is an essential tool for most sheet metal fabrication shops. Whether you are a small shop or large, the right sheet metal forming equipment can make all the difference in your production. But what do you need? And where should you invest to get the best value for your money? In this article, I will go over everything you need to know about choosing and investing in sheet metal forming equipment.

How Does Sheet Metal Forming Equipment in Rockford Works?

First of all sheet metal forming equipment is, well it’s complicated. It basically works by using air pressure to push sheet materials into die tooling (the machine that makes the shape). The sheet material is pushed through a series of rollers and dies until its contours match those of the die-cut tools.

Types of sheet metal forming equipment

There are three main types of sheet metal fabricators; manual presses, mechanical press brakes & CNC punch machines. Each has its benefits but I will focus on what you need for your shop if you already have or want to invest in some form of automated machinery.

Knowing what Kind of Sheet Metal Forming Equipment to Invest

The first thing you need to know is what kind of sheet metal forming equipment in Rockford should I invest in? You have a few options here. Traditional or manual tools are great for small shops and those on a budget, but there are limitations as far as production goes. For larger operations that want to maximize their productivity, automated tools will be your best bet. You’ll be able to run multiple jobs at the same time and produce much more in a shorter amount of time!

Now that you’ve got your equipment, how do you know if it’s in good working order? If possible, bring someone in who has experience with sheet metal forming equipment in Rockford! They can inspect your equipment, provide maintenance and even help you choose the best new tools to meet your needs. The advantages and disadvantages of using sheet metal forming equipment in your company’s production process. It can be a large investment, but it can also increase productivity and decrease downtime.

Sheet metal is used in many different applications to create uniform parts that have the same size and shape. One of the ways sheet metal can be formed into these shapes is through sheet-metal forming equipment like press brakes, ironworkers (also called punch presses), shears, rolling mills, or roll formers which are all common pieces of machinery for any sheet-metal shop! Make sure you choose an option that will fit your specific industry’s needs most efficiently since they each come with their own pros and cons. For example; if you need something portable for traveling between job sites then choosing linear tooling would make sense while stationary sheet-metal shops might benefit from a sheet metal press brake to have the ability to perform multiple tasks.

If you are looking for sheet metal equipment, browse our website today!